Automotive Marking

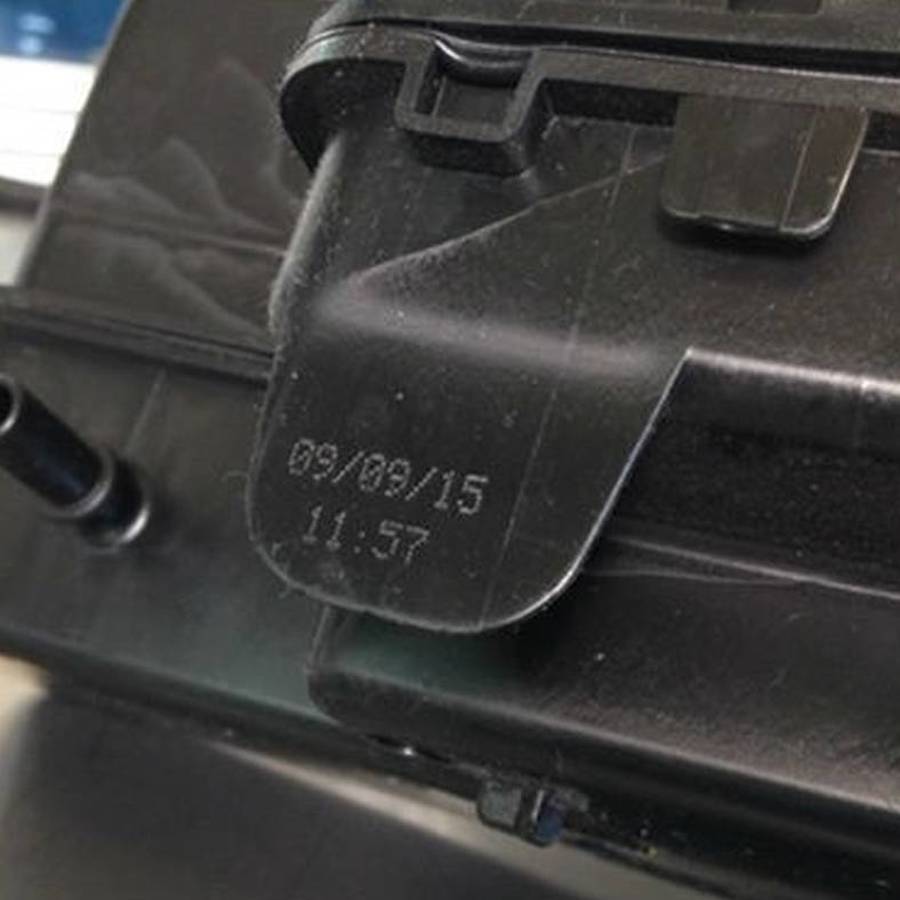

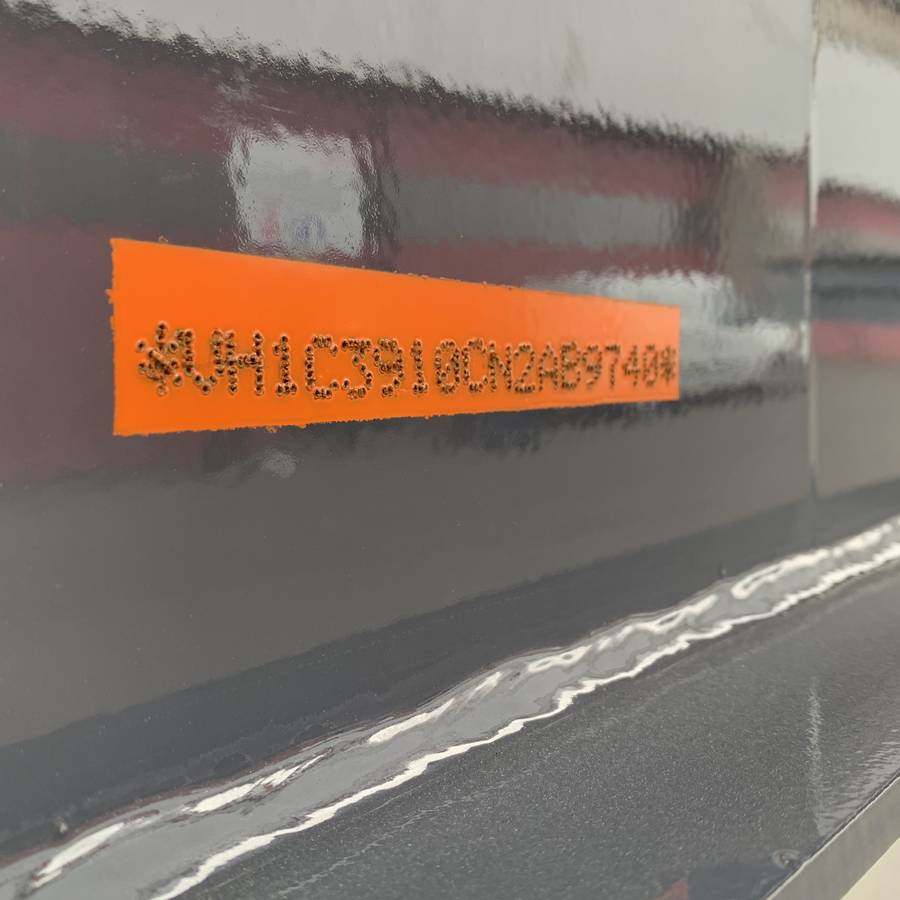

Universal Marking Solutions provides a range of marking solutions that are perfectly adapted for the demands of automotive marking. Laser, dot peen and electrochemical marking are all commonly used in automotive marking applications. Dot peen marks are able to withstand heavy use, painting, coating and galvanising. Contact us for more information on the capabilities of automotive marking at info@ums.co.uk or call us on 01420 565 800